Enhancing Home Safety with Firewrapping HVAC Ductwork

In this article, we explore the critical role of firewrapping in HVAC ductwork, a key aspect of building safety often overlooked by homeowners.

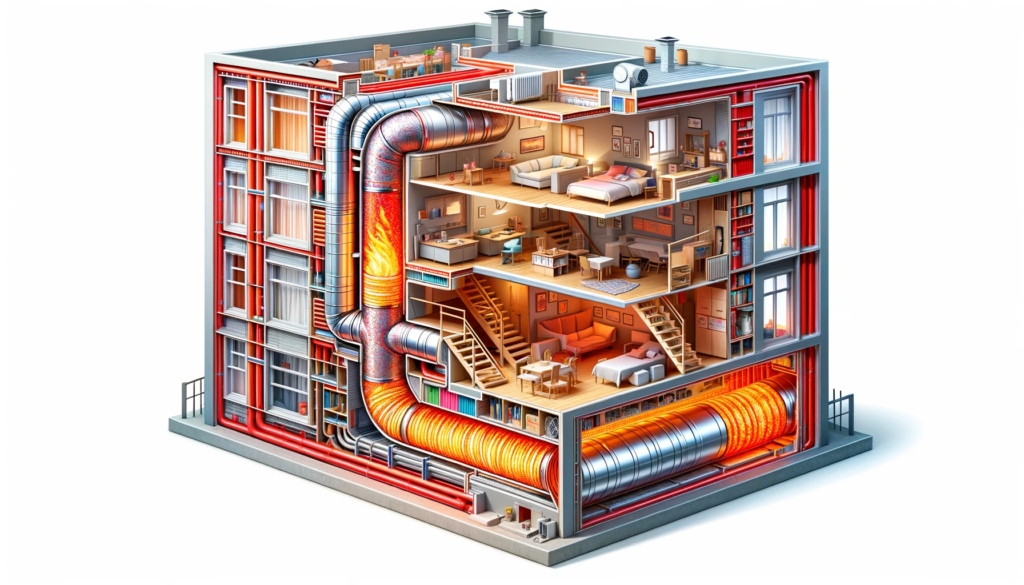

Understanding Firewrapping in HVAC Systems

Firewrapping HVAC ductwork involves using fire-resistant materials to wrap the ducts, reducing the risk of fire and smoke spread throughout a building. This practice is essential in both residential and commercial structures for ensuring safety in the event of a fire.

Why is Firewrapping Crucial?

-

Fire and Smoke Containment: Properly firewrapped ducts can significantly slow down the spread of fire and smoke, buying crucial time for evacuation and response.

-

Material Integrity: Firewrapping materials are designed to withstand high temperatures, thereby maintaining the structural integrity of the ductwork during a fire.

-

Compliance with Safety Regulations: Many building codes mandate firewrapping for HVAC ductwork, making it not only a safety measure but also a compliance requirement.

Firewrapping Techniques

-

Use of Fire-Resistant Wraps: Specialized wraps, often made of fiberglass or other non-combustible materials, are used to encase the ductwork.

-

Sealing and Insulation: Joints and seams in the ductwork are sealed with fire-resistant sealants to prevent the passage of smoke and flames.

Choosing the Right Materials

Selecting appropriate firewrapping materials is crucial. Materials like fiberglass have been extensively tested for fire resistance and safety, offering reliable protection in case of a fire.

In conclusion, firewrapping your HVAC ductwork is a crucial step in enhancing the safety and resilience of your home against fire hazards. It’s an investment in peace of mind, knowing that your home is better protected against the unexpected.